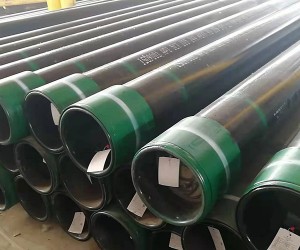

Drill Pipe For Chinese Factories

Drill pipe is made from the welding of at least three separate pieces: box tool joint, pin tool joint, and the tube. The ends of the tubes are then upset to increase the cross-sectional area of the ends. The tube end may be externally upset (EU), internally upset (IU), or internally and externally upset (IEU). Standard max upset dimensions are specified in API 5DP, but the exact dimensions of the upset are proprietary to the manufacturer. After upsetting, the tube then goes through a heat treating process. Drill pipe steel is commonly quenched and tempered to achieve high yield strengths

Drill pipe is a kind of steel tubes with threaded tail, mainly used to connect the surface equipment of drilling rig and drilling and grinding equipment or bottom hole device at the bottom of drilling. The purpose of the drill pipe is to transport drilling mud to the bit and to raise, lower or rotate the bottom hole device together with the bit. The drill pipe must be able to withstand large internal and external pressure, twist, bending and vibration. In the process of oil and gas extraction, drill pipe can be used many times. Drill pipe is can bo divided into three types: Kelly, drill pipe and weighted drill pipe

What size is drill pipe?

Standard drill pipes usual is 31 feett long section of tubes pipe.but may be anywhere from 18 to 45 feet in length..

What is drill pipe in oil and gas?

Drill Pipe is a tube shaped conduit made of steel that is fitted with specially made threaded ends that are known as tool joints. Drill stems have a thin walled tubular casing for tapping the natural resources that are present in the oil reservoirs

What is a drill pipe connection?

Every section of drill pipe is fitted with two ends, which are added to the pipe after manufacturing and are called tool joints. Tool joints provide high-strength, threaded connections that can withstand large amounts of pressure.The female end, or “box”, is threaded on the inside of the pipe

How are drill pipes classified?

Drill pipe is most often considered premium class, which is 80% remaining body wall (RBW). After inspection determines that the RBW is below 80%, the pipe is considered to be Class 2 or "yellow band" pipe. Eventually the drill pipe will be graded as scrap and marked with a red band.

How long is a stand of drill pipe?

The drill pipe “joints” are made in 31.6 ft (9.6 m) lengths and are run and stored horizontally on the ship in three-joint sections known as “triples” or “stands”

What is an API thread?

API Coupling refers to the steel couplings that used in connecting casing pipe and tubing. Also known by OCTG coupling, it is usually manufactured in seamless type, material grade same with the pipe body (API 5CT K55/J55, N80, L80, P110 etc), same PSL or providing higher grades than requested

Oilfield Pipe

This steel tubing is typically made of iron or steel and some still have couplings attached. They are a great structural material.

What is the difference between drill pipe and drill collar?

The average length of both a drill pipe and a drill collar are both around 31 feet. Drill collars also have a larger outer diameter and smaller inner diameter than drill pipe. This means that the threaded ends can be machined directly onto the drill collar, and not applied after production, as with drill pipe.

How strong is drill pipe?

IS 135 ksi

Drill pipe steel is commonly quenched and tempered to achieve high yield strengths (135 ksi is a common tube yield strength).

How long is a stand of drill pipe?

The drill pipe “joints” are made in 31.6 ft (9.6 m) lengths and are run and stored horizontally on the ship in three-joint sections known as “triples” or “stands” (Fig.

How long is oilfield pipe?

around 30 ft

A length of pipe, usually referring to drillpipe, casing or tubing. While there are different standard lengths, the most common drillpipe joint length is around 30 ft [9 m]. For casing, the most common length of a joint is 40 ft [12 m].

total length of the string of drill collars may range from about 100 to 700 ft or longer. The purpose of drill collars is to furnish weight to the bit

What is heavy weight drill pipe?

A Heavy Weight Drill Pipe (HWDP) looks like a normal drill pipe except for an upset centered along the tube which helps to prevent excessive buckling. ... HWDP is used most commonly in directional drilling because it bends more easily and helps to control torque and fatigue in high-angle operations