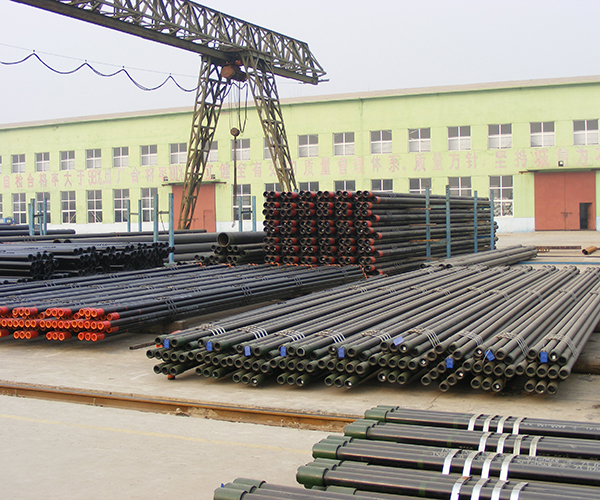

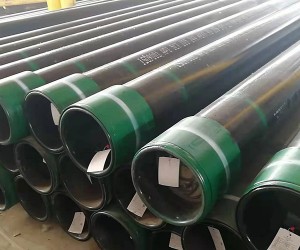

API 5CT J55 Casing pipes Manufacturer

1. Outer diameter

4 1/2″, 5″, 5 1/2″, 6 5/8″, 7″, 7 5/8″, 9 5/8″, 10 3/4″, 13 3/8″, 16″, 18 5/8″, 20″, 30″

2. Wall thickness

5.21 – 16.13 mm

3. Thread type

SC(Short round thread), LC(Long round thread), BC(Buttress thread), Other Premium Thread

4. Length

|

length |

|||

|

Project |

R1 |

R2 |

R3 |

|

Tubing |

6.10-7.32m |

8.53-9.75m |

11.58-12.80m |

|

Casing |

4.88-7.62m |

7.62-10.36m |

10.36-14.63m |

|

Standard |

Grade |

Composition(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

AIs |

||

|

API SPEC 5CT |

J55K55 |

0.34~0.39 |

0.20~ |

1.25~1.50 |

≤0.020 |

≤0.03 |

≤0.15 |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

(37Mn5) |

||||||||||||

|

N80 |

0.34~0.38 |

0.20~ |

1.45~1.70 |

≤0.020 |

≤0.03 |

≤0.15 |

|

|

|

0.11 |

≤0.020 |

|

|

(36 Mn2V) |

||||||||||||

|

L80(1) |

≤0.43 |

≤0.45 |

≤1.9 |

≤0.03 |

≤0.03 |

|

≤0.25 |

≤0.35 |

|

|

|

|

|

L80(9Cr) |

≤0.15 |

≤1.00 |

0.3~0.60 |

≤0.020 |

≤0.030 |

8~ |

≤0.50 |

≤0.25 |

0.9 ~1.1 |

|

≤0.020 |

|

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.030 |

12.0~ |

≤0.50 |

≤0.25 |

|

|

≤0.020 |

|

|

P110 |

0.26~0.35 |

0.17~ |

0.40~0.70 |

≤0.020 |

≤0.030 |

0.80~ |

≤0.20 |

≤0.20 |

0.15 |

≤0.08 |

≤0.020 |

|

|

(30CrMo) |

||||||||||||

|

Standard |

Grade |

Tensile Strength(MPa) |

Yield Strength(MPa) |

Elongation(%) |

Hardness |

|

API SPEC 5CT |

J55 |

≥517 |

379~552 |

0.5% |

≤241HB |

|

K55 |

≥655 |

379~552 |

0.5% |

||

|

N80 |

≥689 |

552~758 |

0.5% |

||

|

L80(13Cr) |

≥655 |

552~655 |

0.5% |

||

|

P110 |

≥862 |

758~965 |

0.6% |

|

Name |

J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

| Casing | a bright green band | two bright green bands | a bright red band | a bright red band + a green band | a red band + a brown band | a bright white band |

| Coupling | entire green coupling + a white band | entire green coupling | entire red coupling | entire red coupling + a green band | entire red coupling + a brown band | entire white coupling |

| Labels | Outside diameter | T&C | Wall thickness | Type of end-finish | |||||||

| (d/mm) | (kg/m) | (t/mm) | |||||||||

| 1 | 2 | J55/K55 | M65 | L80/R95 | N80-1/Q | C90/T95 | P110 | Q125 | |||

| 2004/1/2 | 9.5 | 114.3 | 14.14 | 5.21 | PS | PS | - | - | - | - | - |

| 10.5 | 114.3 | 15.63 | 5.69 | PSB | PSB | - | - | - | - | - | |

| 11.6 | 114.3 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | - | |

| 13.5 | 114.3 | 20.09 | 7.37 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | PLB | PLB | |

| 5 | 11.5 | 127 | 17.11 | 5.59 | PS | PS | - | - | - | - | - |

| 13 | 127 | 19.35 | 6.43 | PSLB | PSLB | - | - | - | - | - | |

| 15 | 127 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18 | 127 | 26.79 | 9.19 | - | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.4 | 127 | 31.85 | 11.1 | - | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.2 | 127 | 34.53 | 12.14 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 24.1 | 127 | 35.87 | 12.7 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 2005/1/2 | 14 | 139.7 | 20.83 | 6.2 | PS | PS | - | - | - | - | - |

| 15.5 | 139.7 | 23.07 | 6.98 | PSLB | PSLB | - | - | - | - | - | |

| 17 | 139.7 | 25.3 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | - | |

| 20 | 139.7 | 29.76 | 9.17 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 23 | 139.7 | 34.23 | 10.54 | - | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.8 | 139.7 | 39.88 | 12.7 | - | - | - | - | P | - | - | |

| 29.7 | 139.7 | 44.2 | 14.27 | - | - | - | - | P | - | - | |

| 32.6 | 139.7 | 48.52 | 15.88 | - | - | - | - | P | - | - | |

| 35.3 | 139.7 | 52.53 | 17.45 | - | - | - | - | P | - | - | |

| 38 | 139.7 | 56.55 | 19.05 | - | - | - | - | P | - | - | |

| 40.5 | 139.7 | 60.27 | 20.62 | - | - | - | - | P | - | - | |

| 43.1 | 139.7 | 64.14 | 22.22 | - | - | - | - | P | - | - | |

| 2006/5/8 | 20 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | - | - | - | - | - |

| 24 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | - | |

| 28 | 168.28 | 41.67 | 10.59 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 32 | 168.28 | 47.62 | 12.06 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17 | 177.8 | 25.3 | 5.87 | - | - | - | - | - | - | - |

| 20 | 177.8 | 29.76 | 6.91 | PS | PS | - | - | - | - | - | |

| 23 | 177.8 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | - | - | |

| 26 | 177.8 | 38.69 | 9.19 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 29 | 177.8 | 43.16 | 10.36 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 32 | 177.8 | 47.62 | 11.51 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 35 | 177.8 | 52.09 | 12.65 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 38 | 177.8 | 56.55 | 13.72 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 42.7 | 177.8 | 63.55 | 15.88 | - | - | - | - | P | - | - | |

| 46.4 | 177.8 | 69.05 | 17.45 | - | - | - | - | P | - | - | |

| 50.1 | 177.8 | 74.56 | 19.05 | - | - | - | - | P | - | - | |

| 53.6 | 177.8 | 79.77 | 20.62 | - | - | - | - | P | - | - | |

| 57.1 | 177.8 | 84.98 | 22.22 | - | - | - | - | P | - | - | |

| 2007/5/8 | 24 | 193.68 | 35.72 | 7.62 | - | - | - | - | - | - | |

| 26.4 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | - | - | |

| 29.7 | 193.68 | 44.2 | 9.52 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 33.7 | 193.68 | 50.15 | 10.92 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 39 | 193.68 | 58.04 | 12.7 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 42.8 | 193.68 | 63.69 | 14.27 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 45.3 | 193.68 | 67.42 | 15.11 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 47.1 | 193.68 | 70.09 | 15.88 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 51.2 | 193.68 | 76.2 | 17.45 | - | - | - | - | P | - | - | |

| 55.3 | 193.68 | 82.3 | 19.05 | - | - | - | - | P | - | - | |

| 2007/3/4 | 46.1 | 196.85 | 68.61 | 15.11 | - | - | P | P | P | P | P |

| 2008/5/8 | 24 | 219.08 | 35.72 | 6.71 | PS | PS | - | - | - | - | - |

| 28 | 219.08 | 41.67 | 7.72 | PS | - | - | - | - | - | ||

| 32 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | - | - | - | - | - | |

| 36 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | - | |

| 40 | 219.08 | 59.53 | 11.43 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 44 | 219.08 | 65.48 | 12.7 | - | - | PLB | PLB | PLB | PLB | - | |

| 49 | 219.08 | 72.92 | 14.15 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 2009/5/8 | 32.3 | 244.48 | 48.07 | 7.92 | - | - | - | - | - | - | - |

| 36 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | - | - | - | - | - | |

| 40 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | - | - | |

| 43.5 | 244.48 | 64.74 | 11.05 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 47 | 244.48 | 69.95 | 11.99 | - | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.5 | 244.48 | 79.62 | 13.84 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 58.4 | 244.48 | 86.91 | 15.11 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 59.4 | 244.48 | 88.4 | 15.47 | - | - | - | - | P | - | - | |

| 64.9 | 244.48 | 96.58 | 17.07 | - | - | - | - | P | - | - | |

| 70.3 | 244.48 | 104.62 | 18.64 | - | - | - | - | P | - | - | |

| 75.6 | 244.48 | 112.51 | 20.24 | - | - | - | - | P | - | - | |

| 2010/3/4 | 32.75 | 273.05 | 48.74 | 7.09 | - | - | - | - | - | - | - |

| 40.5 | 273.05 | 60.27 | 8.89 | PSB | PSB | - | - | - | - | - | |

| 45.5 | 273.05 | 67.71 | 10.16 | PSB | PSB | - | - | - | - | - | |

| 51 | 273.05 | 75.9 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | - | |

| 55.5 | 273.05 | 82.6 | 12.57 | - | PSB | PSB | PSB | PSB | PSB | - | |

| 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | PSB | PSB | PSB | |

| 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | PSB | PSB | PSB | |

| 73.2 | 273.05 | 108.94 | 17.07 | - | - | - | - | P | - | - | |

| 79.2 | 273.05 | 117.87 | 18.64 | - | - | - | - | P | - | - | |

| 85.3 | 273.05 | 126.94 | 20.24 | - | - | - | - | P | - | - | |

| 2011/3/4 | 42 | 298.45 | 62.5 | 8.46 | - | - | - | - | - | - | - |

| 47 | 298.45 | 69.95 | 9.53 | PSB | PSB | - | - | - | - | - | |

| 54 | 298.45 | 80.36 | 11.05 | PSB | PSB | - | - | - | - | - | |

| 60 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65 | 298.45 | 96.73 | 13.56 | - | - | P | P | P | P | P | |

| 71 | 298.45 | 105.66 | 14.78 | - | - | P | P | P | P | P | |

| 2013/3/8 | 48 | 339.72 | 71.43 | 8.38 | - | - | - | - | - | - | - |

| 54.5 | 339.72 | 81.11 | 9.65 | PSB | PSB | - | - | - | - | - | |

| 61 | 339.72 | 90.78 | 10.92 | PSB | PSB | - | - | - | - | - | |

| 68 | 339.72 | 101.2 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | - | |

| 72 | 339.72 | 107.15 | 13.06 | - | - | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65 | 406.4 | 96.73 | 9.53 | - | - | - | - | - | - | - |

| 75 | 406.4 | 111.62 | 11.13 | PSB | PSB | - | - | - | - | - | |

| 84 | 406.4 | 125.01 | 12.57 | PSB | PSB | - | - | - | - | - | |

| 109 | 406.4 | 162.21 | 16.66 | P | - | P | P | - | P | P | |

| 2018/5/8 | 87.5 | 473.08 | 130.22 | 11.05 | PSB | PSB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | PSLB | PSLB | - | - | - | - | - |

| 106.5 | 508 | 158.49 | 12.7 | PSLB | PSLB | - | - | - | - | - | |

| 133 | 508 | 197.93 | 16.13 | PSLB | - | - | - | - | - | - | |